6 Axis 3D Printing

Robotic Experiments

Robotic Fabrication Course

Material Topology Research Laboratory (MTRL)

In collaboration with Kobi Laham HaCohen

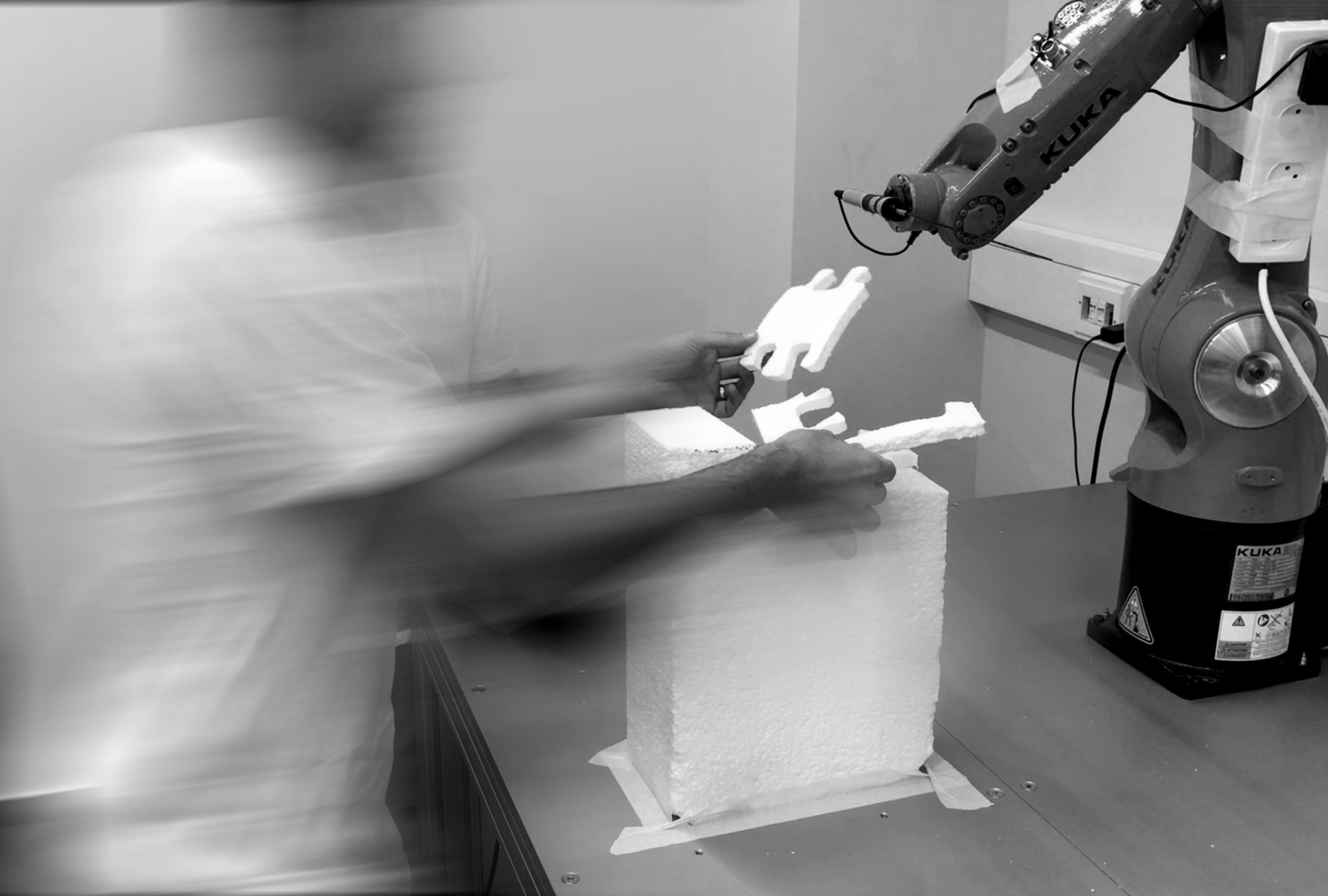

The course focused on the analysis of existing manufacturing practices and their transfer into robotic fabrication, with an emphasis on developing tools, toolpath planning and physical production of architectural elements. As part of the course, the students were exposed to the specific challenges resulting from a combination of tools and concepts from the manual and robotic production world, and acquired tools to translate manual actions into robotic procedures by developing methods for processing materials, manufacturing procedures, and robot control.

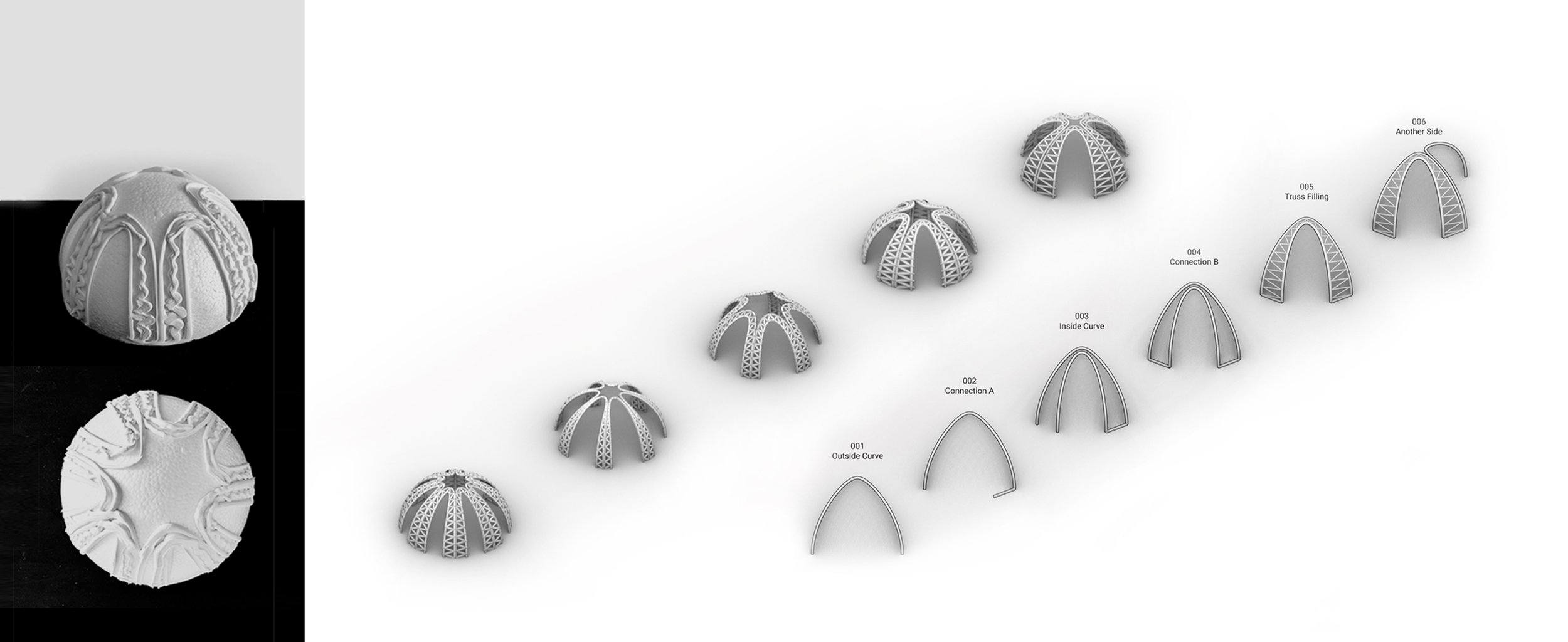

Experiment A - 6 Axis 3D Printing Using Silicone Air Pressure Gun (Left): The experiment follows the idea of a few portable robotic arms being able to print on a topographic landscape or any existing form. One possible scenario would be printing concrete on an inflatable dome and removing it once the concrete became fully dried.

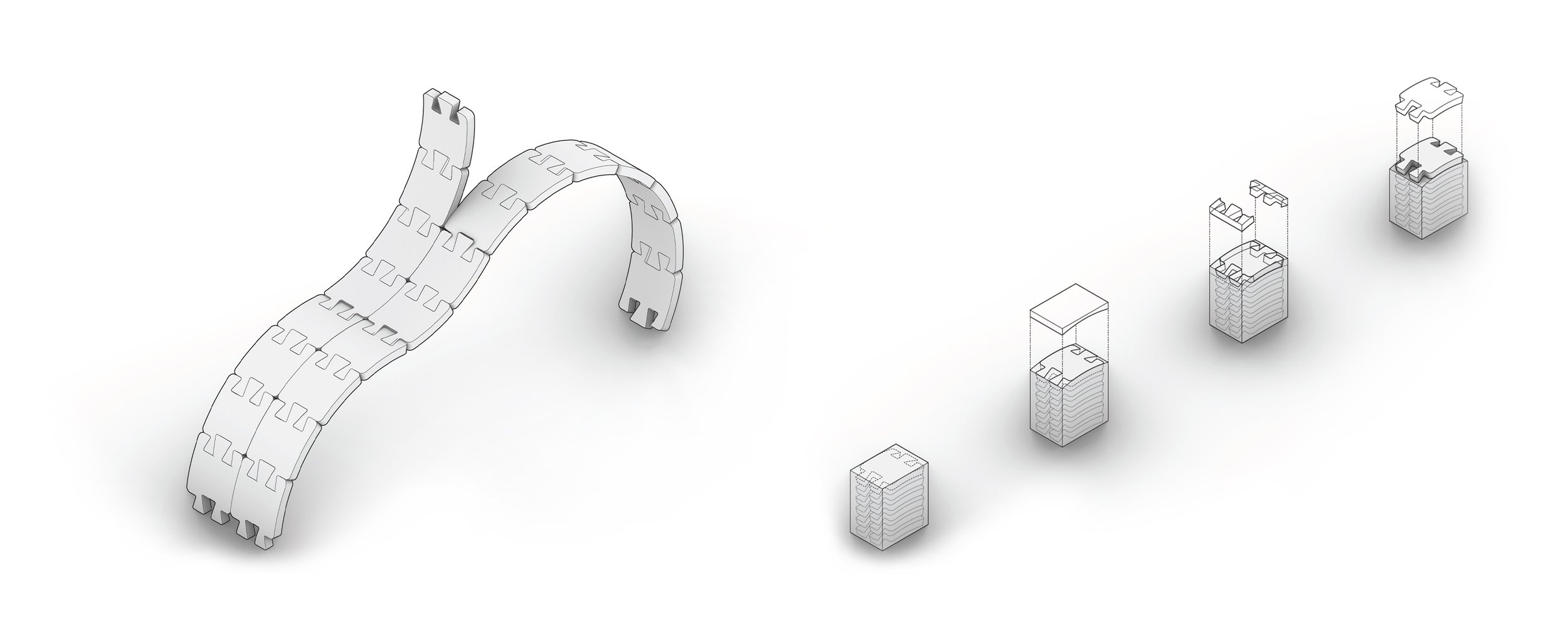

Experiment B - Substracted Elements (Right): The idea of this experiment was to create a spatial structure made by a relatively small piece of foam. In order to achieve this goal, the design was made of a connectable form that can be efficiently packed, and has the ability to be cut in one continued movement. The structure is changeable according to the angle of the pieces connected to each other, making it possible to either create a pure arch shape or a more wave-like shape.

Experiment A - 6 Axis 3D Printing

Results (left), Shape Variety and robot movement (right)

Full Scale Concept

Experiment B - Substracted Elements

Robot movement and shape (left), Suggested use (right)